Painting Process for Boeing:

- Primer

BMS 10-11 Type I: BAC 5736

- Topcoat BMS 10-11 Type II: BAC 5736

- Epoxy Primer BMS 10-79: BAC 5882

Painting Process for Airbus:

- Structural Paints: AIPI 05-02-009

- Structural Paints: AIPS 05-02-009

- Primer(P60-A): APB 4-1123

- Topcoat (F70-A): ABP 4-2130

- Polyurethane Finish: ABP 4-2364

NDT Specification for Boeing:

- Liquid Penetrant Inspection: BAC5423, BSS7039

NDT Specification for

Airbus:

- Liquid Penetrant Inspection: ABP 6-5230, AITM 6-1001

- .

- .

- .

- .

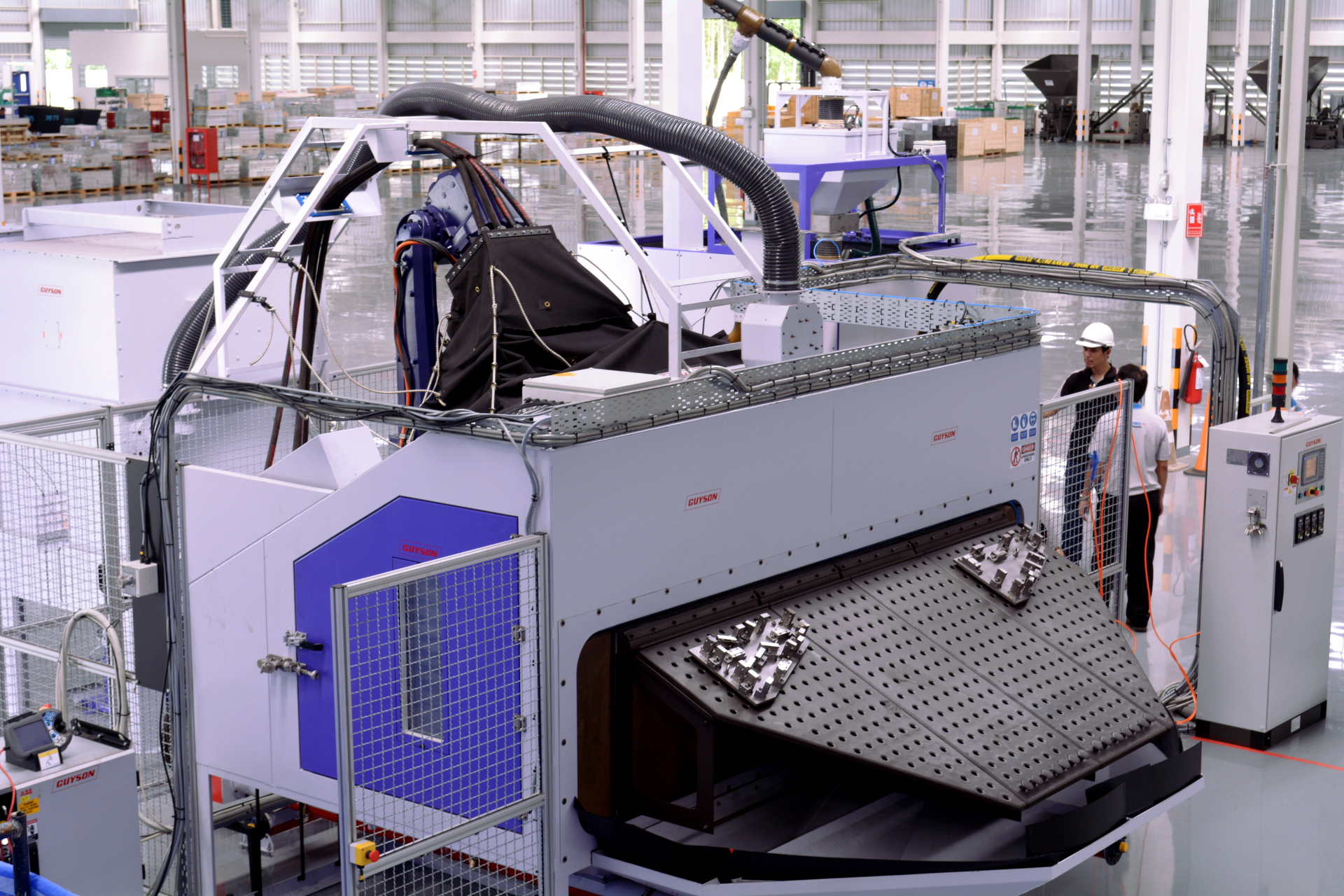

Shot Peening for Boeing:- Robotic Shot Peening: BAC 5730

- Self-Contained Shot peen (Flapper penning) for Boeing : BAC5730-2

Shot Peening for Airbus:

- Robotic Shot Peening:

AIPI 02-02-004, AIPS 02-02-004

- .

- .

- .

- .

- .

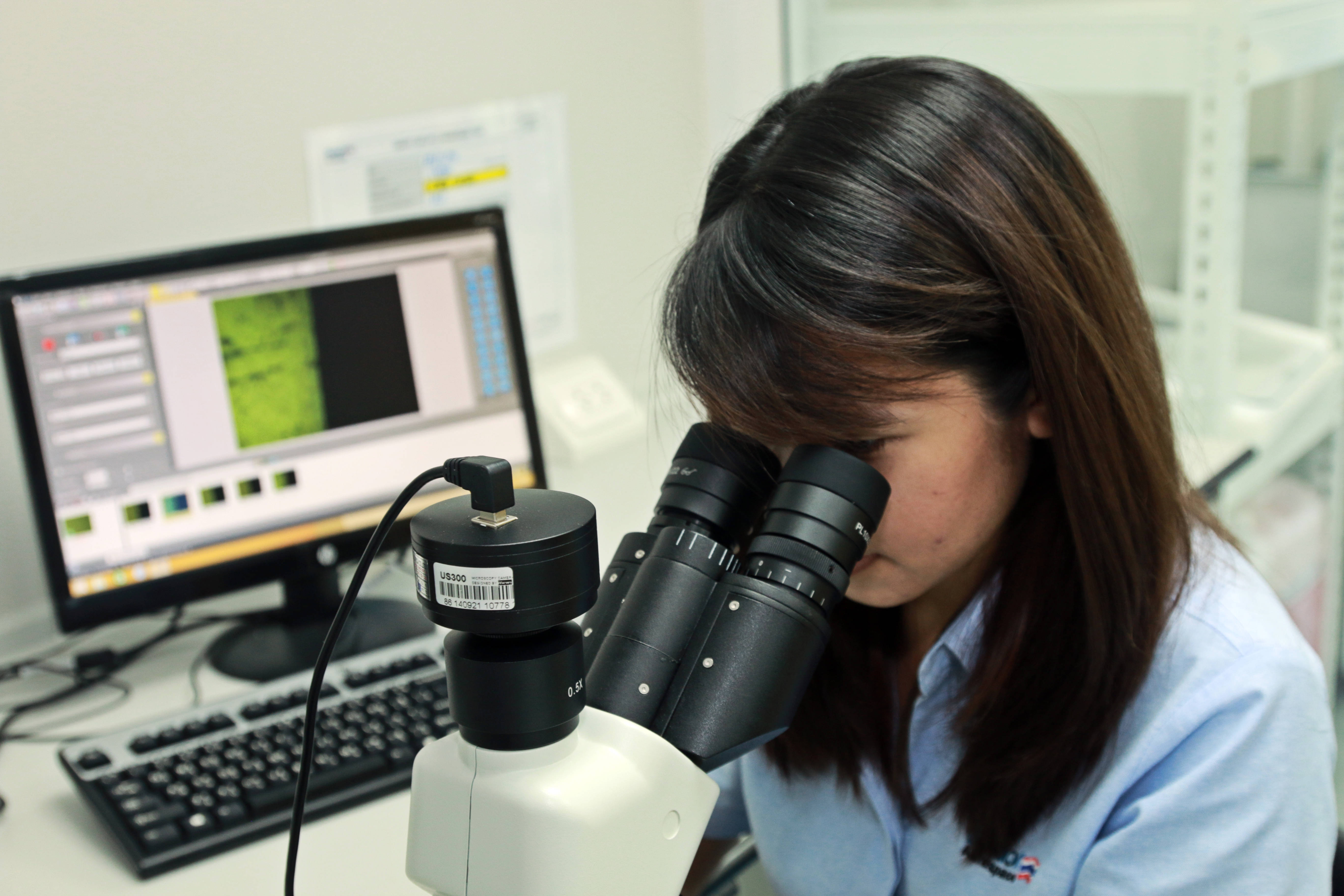

Laboratory testing:

Roughness

- Roughness Tester: BACD2079

Chemical solution analysis- Auto Titration: AITM3-0030

- pH Meter: AITM3-0032

- Conductivity Meter: AITM3-0035

- Inductively Coupled Plasma (ICP): AITM3-0038

- UV Spectrophotometer: ISO11885

Corrosion- Salt Spray Testing Machine: ISO9227

- Microscope 1X – 4.5X: ASTM B-117

Paint adhesion- Cross Cut Adhesion Test Kit: ISO2409

- Magnification 3X:

ISO2409

IGA (Intergranular Attack) & EGP (End Grain Pitting) Micro Structure- Grinding Machine: ASTM F2111

- Cutting Machine:

ASTM F2111

- Microscope 5X-100X:

ASTM F2111

Coating weight

- Digital Weight Balance: ASTM B-137

Coating thickness- Coating Thickness Gauge: ISO2808

Chemical Processing for Boeing:

- Pre-Penetrant Etching: BAC 5786

- Anodizing Process: Boric-Sulfuric Anodizing (BSA): BAC 5632

- Chemical Conversion Coating (Alondine1200S): BAC 5719

Chemical Processing for Airbus:

- Pre-Penetrant Etching: APB 8-2297

- Anodizing Process: Tartaric-Sulfuric Anodizing (TSA): AIPI 02-01-003, AIPS 02-01-003

- Chemical Conversion Coating (Alondine1200S): ABP 1-5057, AIPI 02-05-001, AIPS 02-05-001

Chemical Processing for Zodiac Aerospace:

- Chemical Conversion Coating: EPS 2018

Assembly Process for Boeing:

- SEALING, GENERAL:

BAC5000

- INSTALLATION OF PERMANENT FASTENERS:

BAC5004

- Fastener Installation in Composite Structures: BAC5063

- ELECTRICAL BONDING:

BAC5117

- PART MARKING:

BAC5307

- BEARING INSTALLATION AND RETENTION: BAC5435

Assembly Process for Airbus:

- RIVETING WITH BLIND NUT PLATE RIVETS: ABP 2-1065

- MANUAL RIVETTING WITH PREFORMED SOLID RIVETS: ABP 2-1072

- SHRINK FITTING OF BOLTS BUSHES PINS AND OTHER FASTENING PARTS: ABP 2-2082

- APPLICATION OF SEALANT FOR INTEGRAL FUEL TANKS: ABP 4-5141

- APPLICATION OF SEALANT FOR GENERAL AIRCRAFT STRUCTURE: ABP 4-5142

- ELECTRICAL BONDING OF METALLIC MATERIAL ASSEMBLY METHOD: ABP 7-1245

- BONDING OF BUSH, BALL BEARING AND SPHERICAL BEARINGS: ADET 0033

- INSTALLATION OF BALL BEARING, SPHERICAL BEARING AND BUSHING BY STAKING: ADET 0191

- STRUCTURAL RIVETING: ADET 0078

- APPLICATION OF SEALANT: ADET 0082

- ELECTRICAL BONDING PROCESSES: ADET 0114

- INSTALLATION OF TIGHT FIT BUSHES: ADET 0173

- Preparation of Holes in Metallic Materials for Fastening: AIPS 01-02-003

- Torque tightening of screws, bolts and nuts: AIPS 01-02-008

- General assembly and installation of fasteners: AIPS 01-02-017

- Installation of bearings, spherical bearings and bushes by swaging: AIPS 03-03-012

- Sealing of aircraft structure: AIPS 05-05-001

- Surface protection of fasteners and sealants by application of paint: AIPS 05-05-003

- Wet installation of fasteners: AIPS 05-05-004

- Electrical Bonding: AIPS 07-01-006

- Electrical bonding connections resistance measurement: AITM 6-9008

- COLD BONDING OF BUSHES-BALL BEARINGS-SPHERICAL BEARING: IPDA 77-01

Assembly Process for Zodiac:- LOCTITE ANAEROBIC ADHESIVES AND SEALANT log print: EPS-0001

- LOCTITE CYANOACRYLATE ADHESIVES SUPERGLUE _Log Print: EPS-0003

- ADHESIVES NON STRUCTURAL log print: EPS-0006

- NON STRUCTURAL BONDING USING 3M VHB DOUBLE SIDED TAPE: EPS-0022

- USE AND APPLICATION OF NON-STRUCTURAL ADHESIVE: EPS-0034

- BLIND RIVETS POP: EPS-3000

- METHODS OF MARKING PARTS AND ASSEMBLIES: EPS-3009

- APPLICATION OF HOOK AND LOOP FASTENINGS: EPS-3039

- TORQUE TIGHTENING OF THREADED FASTENERS: EPS-3089

- INSTALLATION OF HELICAL COIL SCREW THREAD INSERTS: EPS-3090

- EARTH STUD HEX HEAD PARTS SELECTION: EPS-4010

- ELECTRICAL GROUNDING AND BONDING: EPS-4072

- ELECTRICAL FAYING SURFACE BONDS: EPS-4097